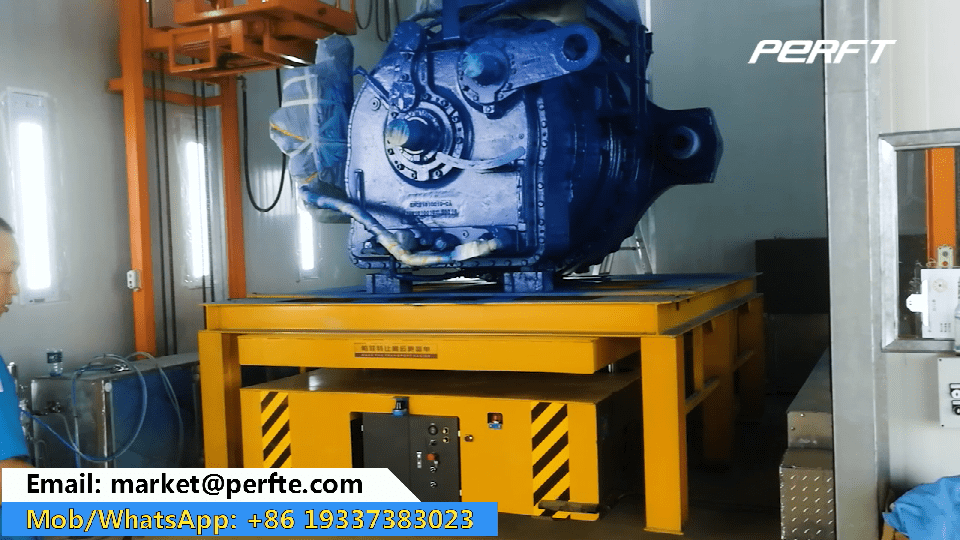

trackless transfer cart with flat deck 120 ton

Trackless transfer cart with flat deck 120 ton electrical engineering control system consists of: control power switch, DC transformer machine equipment, warning light, conductive transfer device, the key effect is to produce the working voltage necessary for the operation of the electric flat deck.

The difference between the Trackless transfer cart with flat deck 120 ton and the hydraulic lift rail trolley is whether it runs on rails or not. The hydraulic lift rail car can turn on the track, but not as much as the trackless transfer cart with flat deck 120 ton moves on the ground. trackless transfer cart with flat deck 120 ton does not need to consider the track laying requirements, the cost of the track and the costs. The trackless transfer cart with flat deck 120 ton has no running route and is more friendly to road conditions. It can run on concrete figure ground, tempered ground, etc. It can achieve 360 degrees and also has a certain climbing ability depending on traction power.

Trackless transfer cart with flat deck 120 ton key has transmission manipulation device, electric engineering manipulation device, cart wheel, window frame composition.

Trackless transfer cart with flat deck 120 ton transmission control system consists of motor, reducer, roller drive belt, braking device and brake control board, the key effect is to drive the electric flat car on the track forward glide.