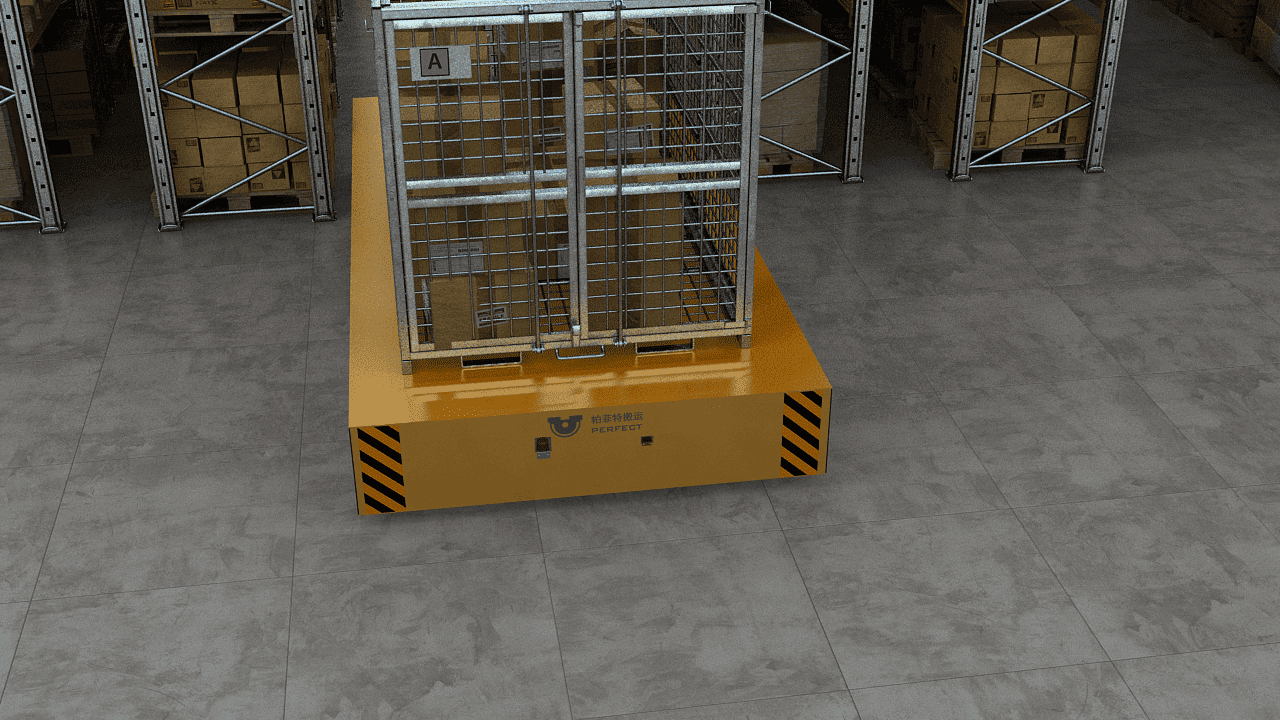

16t Customized Steel Coil Transfer Cart

The 16t customized steel coil transfer cart is a special steel coil transfer trolley equipped with V-shaped brackets and roller brackets to prevent the steel coils from rolling and falling off. At the same time, the roller bracket can adjust the distance according to the diameter of the coil. The V-shaped frame and the roller frame are connected to the car body and can be disassembled at any time to facilitate the transportation of other materials. We can design according to the working conditions of the workshop, the size and weight of the material, and the coil conveying trolley can be used in various occasions and harsh environments.

Parameter for Steel Coil Transfer Cart

| Model | BWP-2T | BWP-10T | BWP-20T | BWP-30T | BWP-50T | BWP-63T | BWP-150T | |

| Rated load (T) | 2 | 10 | 20 | 30 | 50 | 63 | 150 | |

| Table size | length(L) | 2000 | 3600 | 4000 | 4500 | 5500 | 5600 | 10000 |

| Width(W) | 1500 | 2000 | 2200 | 2200 | 2500 | 2500 | 3000 | |

| Height(H) | 450 | 500 | 550 | 600 | 650 | 700 | 1200 | |

| Wheel Base (mm) | 1200 | 2600 | 2800 | 3200 | 4200 | 4300 | 7000 | |

| Wheel Diameter(mm) | Φ270 | Φ300 | Φ350 | Φ400 | Φ500 | Φ600 | Φ600 | |

| Ground Clearance (mm) | 50 | 50 | 50 | 50 | 50 | 75 | 75 | |

| Motor Power (Kw) | 1 | 1.6 | 2.2 | 3.5 | 5 | 6.3 | 15 | |

| Battery Capacity(Ah) | 180 | 160 | 180 | 250 | 330 | 400 | 600 | |

| Battery Voltage(V) | 24 | 48 | 48 | 48 | 48 | 48 | 72 | |

| Running Time When Full Load | 4.32 | 4.8 | 4 | 3.5 | 3.3 | 3 | 2.9 | |

| Running Distance for one Charge(Km) | 6.5 | 7.2 | 4.8 | 4.2 | 4 | 3.6 | 3.2 | |

| Max Wheel Load (KN) | 14.4 | 42.6 | 77.7 | 110.4 | 174 | 221.4 | 265.2 | |

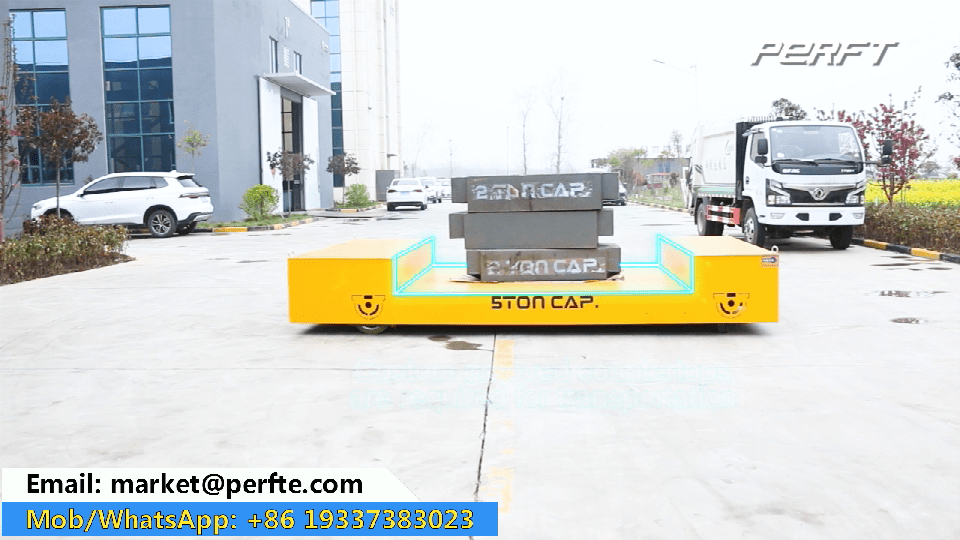

Customized for Steel Coil Transfer Cart

Load capacity and table size can be chosen

Safety devices such as alarm lights, dead man control, and LED display can be designed.

If you have any questions, please feel free to contact us.